SEQUENCING BATCH REACTOR (SBR)

PACT® Sequencing Batch Reactor is a modification of activated sludge process which has been successfully used to treat municipal and industrial wastewater. The difference between a conventional technology and SBR is that the SBR performs equalisation, biological treatment and secondary clarification in a single tank using a times control sequence. It has been very useful in the areas where there is limited amount of space. PACT Sequencing Batch Reactor is a fill and draw activated sludge system. In this system, the waste water is added to a single batch reactor, treated to remove undesirable components and then discharged. There are five stages in the treatment process: fill, react, settle, decant, idle.

The inlet valve opens and the tank is being filled in, while mixing is provided by mechanical means (no air). This stage is also called the anoxic stage. Aeration of the mixed liquor is performed during the second stage by the use of fixed or floating mechanical pumps or by transferring air into fine bubble diffusers fixed to the floor of the tank. No aeration or mixing is provided in the third stage and the settling of suspended solids starts. During the fourth stage the outlet valve opens and the “clean” supernatant liquor exits the tank. The separate treatment of the nitrogen-rich return liquors from sludge treatment represents a special application, which allows increased overall nitrogen removal and a reduction in biological treatment stage loads. Nitrogen removal can be achieved either conventionally with an external substrate for denitrification or using the innovative Anammox process.

ADVANTAGES OF PACT® SBR:

- Equalisation, primary clarification, biological treatment and secondary clarification can be achieved in a single reactor vessel.

- SBR requires small space.

- SBR has controllable react time and quiescent settling.

- Minimal footprint.

- High nutrient removal capabilities.

- The BOD removal efficiency is generally between 85- 90%.

- Filamentous growth elimination.

- A higher degree of operational flexibility with respect to effluent quality and dissolved oxygen (DO) controlled aeration system

- Proven treatment process capacity upgrades and phasing do not require modification or interruption of current treatment process

- Power consumption is typically less than that of a conventional plant with substantial power savings at lower flows

PACT® SBR APPLICATIONS:

- Municipal wastewater including Biological Nutrient Removal

- Water recycle & reuse

- BOD & COD reduction

- Industrial Wastewater

- Food & Beverage

- Pulp & Paper

- Petrochemical & Oil refining

- Chemical/ CPI

- Landfill/ Leachate applications

- Textile Industry

More Products

-

DEMINERALIZATION SYSTEM

PACT® Demineralization is the process of removing mineral salts from water by using the ion exchange process. Demineralised water...

-

REVERSE OSMOSIS DESALINATION SYSTEM

PACT® principals are among the pioneers in the water desalination industry. Since the early 70s PACT® principals have designed...

-

ULTRA FILTRATION (UF)

PACT® Ultra Filtration (UF) involves pressure-driven separation of materials from a feed solution. Ultra filtration membrane productivity is high, while...

-

MULTIMEDIA FILTER

PACT® Multimedia Filter is used to reduce the level of suspended solids in incoming feed water. Suspended solids consists...

-

POTABLE PACKAGE

Water intake at the treatment plant can come from a number of different sources. Surface waters come from rivers,...

-

GREY WATER TREATMENT

Grey water is defined as waste water, collected separately from sewage flow that originates from clothes washer, bathtub, shower...

-

EXTENDED AERATION

PACT® extended aeration process offers certain benefits that can be combined with conventional processes to obtain a high quality...

-

MBBR SYSTEM

Normal biological water treatment is done traditionally by suspended growth mode (e.g. activated sludge and extended aeration process) or...

-

MBR SYSTEM

COMPACT is state o-of-the-art pre-engineered sewage treatment system utilising PACT’s biological treatment expertise with TORAY’s submerged remembrance technology, it...

-

SEQUENCING BATCH REACTOR (SBR)

PACT® Sequencing Batch Reactor is a modification of activated sludge process which has been successfully used to treat municipal...

-

INDUSTRIAL WASTE WATER TREATMENT

PACT® Industrial wastewater treatment – the mechanisms and processes used to treat wastewater that is produced as a by-product...

-

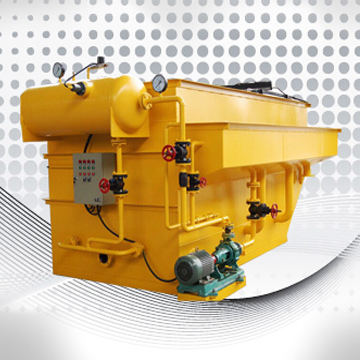

DISSOLVED AIR FLOATATION SYSTEM (DAF)

Dissolved air floatation (DAF) systems are commonly applied to remove suspended solids, fats, oils and associated BOD and COD...

-

GAS ENERGY MIXING SYSTEM (GEM)

PACT’s innovative flocculation and flotation unit is a unique approach and replacement to traditional DAF treatment systems. The GEM unit...

-

DEWATERING PACKAGE & BELT FILTER PRESS

PACT® Dewatering is the simplest definition of the removal of water. This process is used in many industries but...