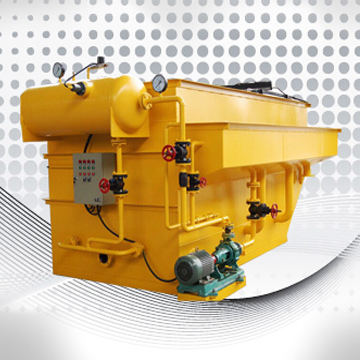

MULTIMEDIA FILTER

PACT® Multimedia Filter is used to reduce the level of suspended solids in incoming feed water. Suspended solids consists of small particles such as slit, clay, grit, organic matter, algae and other micro-organisms. Incoming feed water that is high in suspended solids can cause a high-pressure drop and reduce the effectiveness of downstream filtration equipment such as reverse osmosis membranes and ion exchange beds. A multimedia filter typically consist of three layers of media consisting of anthracite coal, sand and garnet, with a supporting (non filtering) layer of gravel at the bottom.

These are the media of choice because of the differences in size and density. The larger (but lighter) anthracite coal will be top and the heavier (but smaller) garnet will remain at the bottom. The filter media arrangement allows the largest dirt particles to be removed near the top of the media bed with the smaller dirt particles being retained deeper and deeper in the media. This allows the entire bed to act as a filter allowing much longer filter run times between backwash and more efficient particulate removal. A well- operated Multimedia Filter can remove particulates down to 15-20 microns. A Multimedia Filter that uses a coagulant addition (which induces tiny particles to join together to form particles large enough to be filtered) can remove particulates down to 5-10 microns.

PACT® MEDIA FILTERS ADVANTAGES:

- Less or no chemicals required (coagulants, flocculants, disinfectants, pH adjustment)

- Lower energy consumption than nano-filtration or reverse osmosis;

- Constant quality of the treated water in terms of particle and microbial removal. Disinfection through removal of bacteria. To a certain extent, UF allows viruses, phage, colloids and macro molecules to be removed.

- Process and plant compactness

- Simple automation

More Products

-

DEMINERALIZATION SYSTEM

PACT® Demineralization is the process of removing mineral salts from water by using the ion exchange process. Demineralised water...

-

REVERSE OSMOSIS DESALINATION SYSTEM

PACT® principals are among the pioneers in the water desalination industry. Since the early 70s PACT® principals have designed...

-

ULTRA FILTRATION (UF)

PACT® Ultra Filtration (UF) involves pressure-driven separation of materials from a feed solution. Ultra filtration membrane productivity is high, while...

-

MULTIMEDIA FILTER

PACT® Multimedia Filter is used to reduce the level of suspended solids in incoming feed water. Suspended solids consists...

-

POTABLE PACKAGE

Water intake at the treatment plant can come from a number of different sources. Surface waters come from rivers,...

-

GREY WATER TREATMENT

Grey water is defined as waste water, collected separately from sewage flow that originates from clothes washer, bathtub, shower...

-

EXTENDED AERATION

PACT® extended aeration process offers certain benefits that can be combined with conventional processes to obtain a high quality...

-

MBBR SYSTEM

Normal biological water treatment is done traditionally by suspended growth mode (e.g. activated sludge and extended aeration process) or...

-

MBR SYSTEM

COMPACT is state o-of-the-art pre-engineered sewage treatment system utilising PACT’s biological treatment expertise with TORAY’s submerged remembrance technology, it...

-

SEQUENCING BATCH REACTOR (SBR)

PACT® Sequencing Batch Reactor is a modification of activated sludge process which has been successfully used to treat municipal...

-

INDUSTRIAL WASTE WATER TREATMENT

PACT® Industrial wastewater treatment – the mechanisms and processes used to treat wastewater that is produced as a by-product...

-

DISSOLVED AIR FLOATATION SYSTEM (DAF)

Dissolved air floatation (DAF) systems are commonly applied to remove suspended solids, fats, oils and associated BOD and COD...

-

GAS ENERGY MIXING SYSTEM (GEM)

PACT’s innovative flocculation and flotation unit is a unique approach and replacement to traditional DAF treatment systems. The GEM unit...

-

DEWATERING PACKAGE & BELT FILTER PRESS

PACT® Dewatering is the simplest definition of the removal of water. This process is used in many industries but...